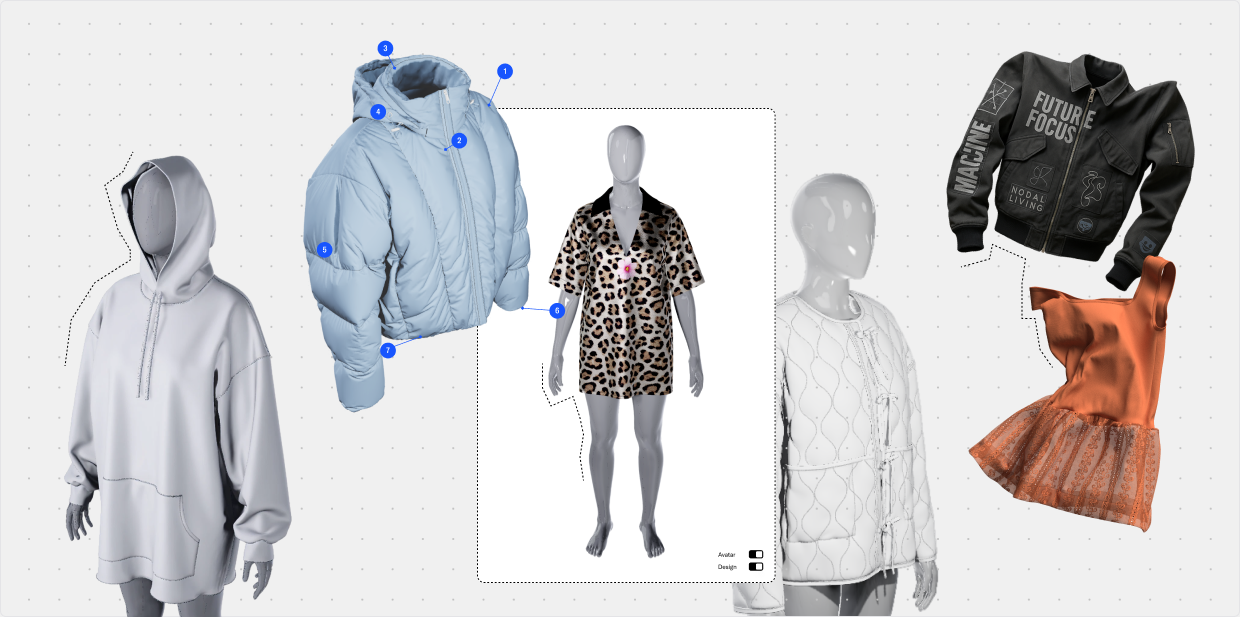

Designing in 3D reduces waste in fashion prototyping

3D design is revolutionizing fashion by cutting waste, reducing costs, and streamlining prototyping—discover how digital tools are reshaping the future of sustainable design.

Many industries are already embracing the power of 3D design, but fashion is just getting started. This shift will not only change how we approach design from concept to prototype, but reduce waste and cost in the process.

In this article, we’ll dive into how digital product creation is slashing waste in fashion prototyping and why it’s quickly becoming the go-to standard for designers like you.

What is 3D design in fashion?

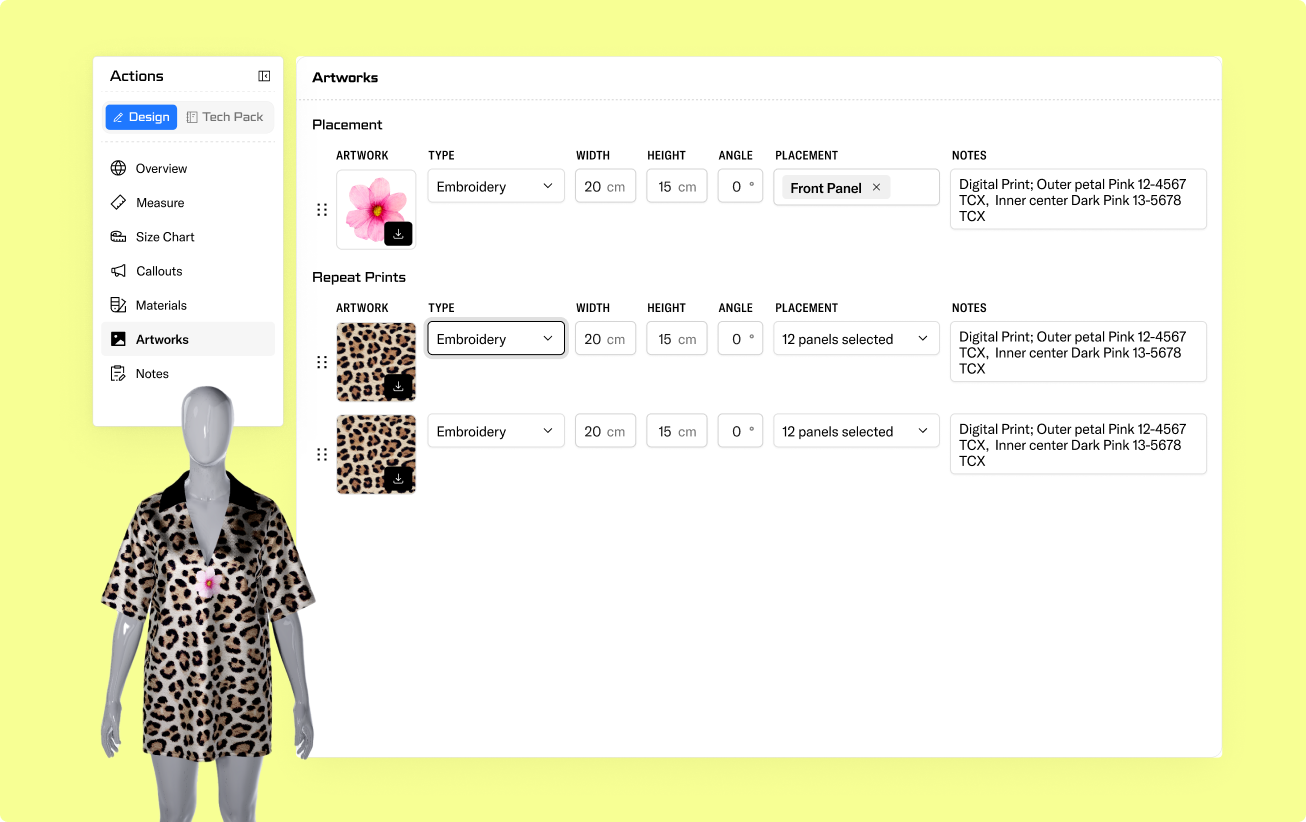

3D design or digital product creation (DPC) is about creating digital models that bring your ideas to life in a whole new way. In the world of fashion, this means you can create digital prototypes of your products, making real-time changes and alterations - all without the need of a physical sample.

The limitations of traditional fashion prototyping

Traditionally, fashion prototyping involves an average of seven iterations per item to test a garment’s design, fit, and fabric. Each alteration or adjustment typically requires a new sample, which results in more fabric, more labor, and more environmental impact. In an industry that is increasingly conscious of its carbon footprint, this approach is not sustainable in the long-run.

“The process of releasing even a basic white t-shirt took six to nine months of sampling and iterations. I had to work with a full product team to produce one item of clothing. Technology is an inevitable solution, and why we started Fabra in the first place,” says Luke Grana, Fabra co-founder.

“The process of releasing even a basic white t-shirt took six to nine months of sampling and iterations. I had to work with a full product team to produce one item of clothing. Technology is an inevitable solution, and why we started Fabra in the first place.”

- Luke Grana, Fabra Co-founder

How 3D design reduces cost and waste

3D tools reduce waste by allowing real-time editing and virtual testing of garments before they are produced. The ability to make adjustments in real-time, viewing how changes will affect the garment’s overall look and fit without ever cutting a piece of fabric results in fewer resources and iterations. This leads to less waste and saving as much as months and thousands of dollars in the sampling process.

“As a physical sample wouldn’t have all the associated data [that a 3D asset has]. And as samples evolve and change, understanding the impact of change on cost, both fabric, trim and make in real time, makes the 3D asset hugely valuable – much more so than a representation of a physical sample,” Mark Charlton tells The Interline.

Current industry applications

Brands we know and love are already integrating 3D digital technology into their workflow and marketing. We’re seeing collaborations between fashion houses and gaming companies that continue to blur the lines between physical and digital experiences. Hugo Boss positions itself as an industry leader when it comes to tech implementation, announcing their goal of reaching 90% 3D product development by 2025. We’re also seeing brands like Levi’s utilizing digital twin technology to create better fitting products.

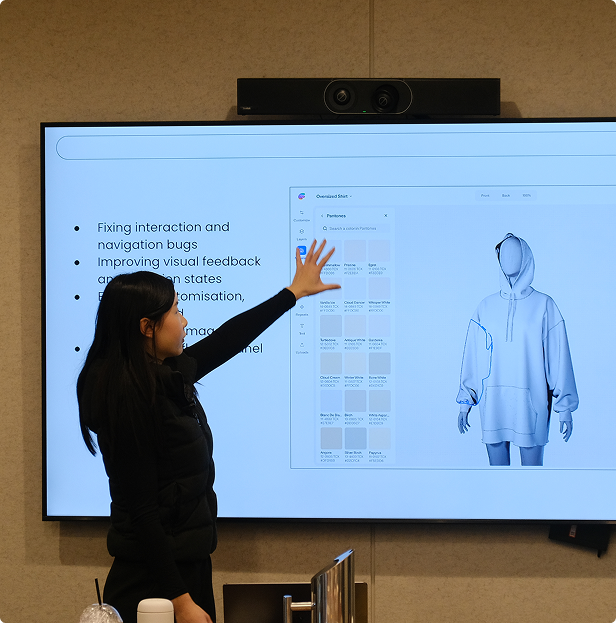

Change is already happening, and designers have the opportunity to begin implementing 3D technology into their workflows or risk being left behind.

Challenges and considerations

Making the switch to DPC is exciting, but isn’t without its challenges. For many brands, the upfront cost of software and training can be a bit steep, and there’s a learning curve as designers get used to new tools and workflows.

If you’re thinking about making the jump to 3D design, it’s a good idea to start looking into user-friendly software like Fabra. As the tech keeps evolving, those who dive in early will probably find themselves ahead of the game when it comes to innovation and sustainability.

The future of fashion

The fashion industry is at a turning point, where sustainability and efficiency are just as important as creativity. DPC offers a great solution for boosting efficiency and reducing waste and cost in fashion design and prototyping. It’s exciting to see more brands and designers embracing this technology to create products that are not only better for the environment, but for the end consumer as well.

Sustainable design with Fabra

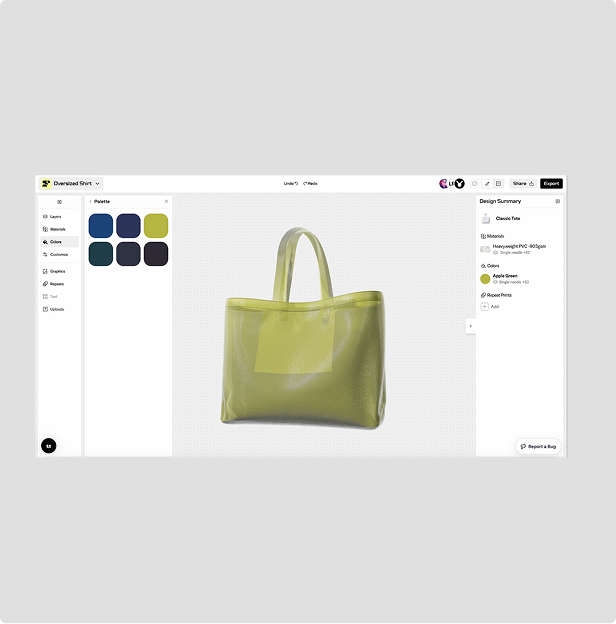

Here at Fabra, we’re committed to providing sustainable solutions to product creators and designers. That’s why we designed our 3D design editor with easy-to-use templates, creative flexibility and real-time 3D fit previews. If you’re a brand or retailer looking to streamline your product sourcing process, or you’re looking to create your own custom merch, Fabra might just be the solution for you.

Idea in there? Get it in Fabra. Start designing today.